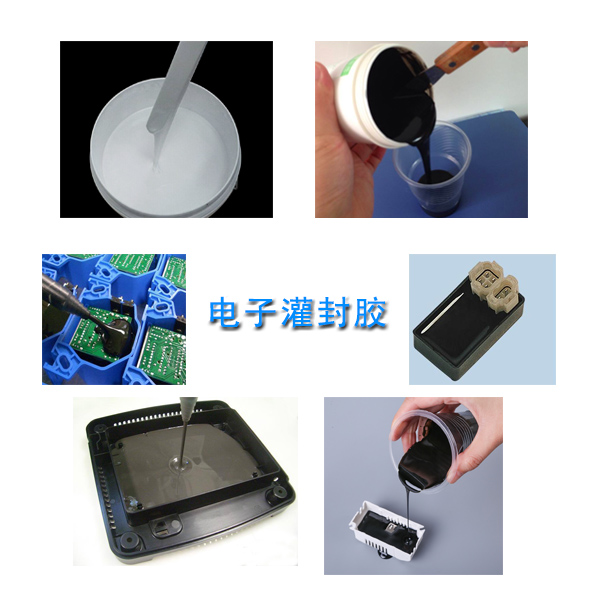

Epoxy potting and silicone potting are both electronic potting, but the hardness and use of the two pottings are different.

Epoxy potting compound is passed the EU ROHS specified standard, and the hardness of the cured product is high. It can be cured at room temperature or by heating. It is a room temperature curing type two-component epoxy resin potting material. It has excellent electrical properties, high surface gloss and easy operation. Mainly used for potting of small and medium-sized electronic components, such as car, motorcycle igniter, LED drive power, sensors, capacitors, triggers, LED waterproof lights, circuit board confidentiality, insulation, moisture-proof (water) potting.

Silicone potting glue can be divided into many types. The properties of different types of silicone potting glues are also very different, such as temperature resistance, water resistance, insulation properties, optical properties and adhesion to different materials. At the same time, external fillers can be added to add some characteristic properties, such as heat conduction and conduction. Silicone potting compound has poor mechanical strength. If a component fails, just open the potting compound and replace it with a new one. It can be used continuously. It can be opened for easy maintenance. Two-component silicone encapsulants are common and widely used. Two-component silicone encapsulants can be classified into condensation type and addition potting compound. Silicone potting compound is used for waterproofing, moisture-proof, gas-proof coating, casting and potting protection of precision electronic components, solar energy, backlights and electrical modules.

In terms of hardness after curing, silicone potting glue is softer than epoxy potting glue. The hardness and color of the silicone potting compound can be adjusted according to the customer's preference and product characteristics, and the conventional color is transparent or translucent.